Tungsten Type Cleaners

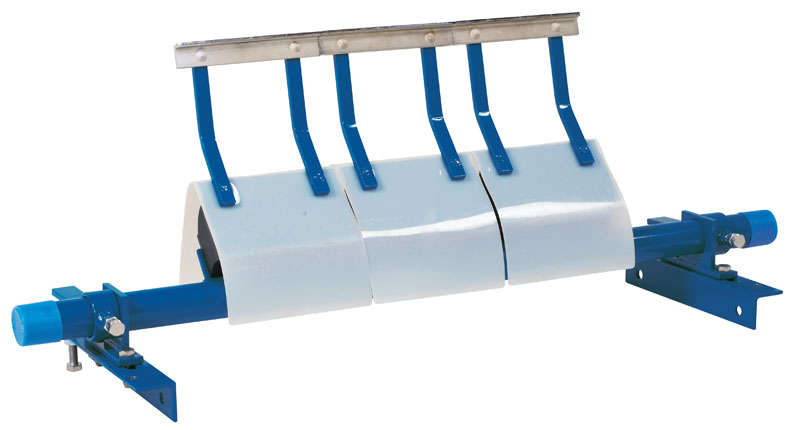

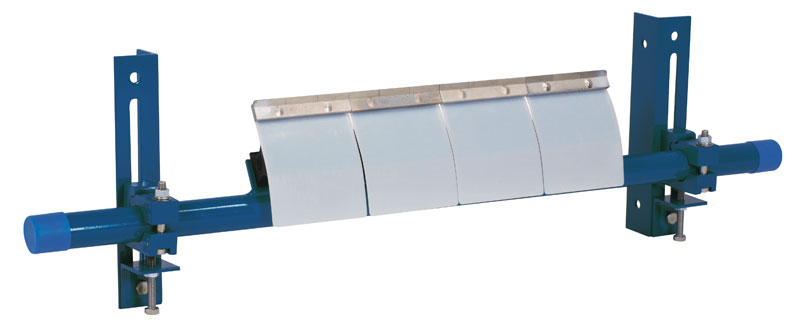

Primary Cleaner

Easy to install, forward and reverse rotation compatible. The Primary cleaner is designed to go on the head drum. Unlike ordinary cleaners with one piece blade it has multi-blade system. This allows the tungsten carbide blades to contour to the belt surface with constant pressure applied by rubber cushions.

Features:

- Tungsten carbide blades for hard wearing, enabling a longer blade life

- High cleaning efficiency

- Essay installation, in small spaces

- Simple to adjust and maintain

- The range of cleaning widths is 300mm to 1700mm

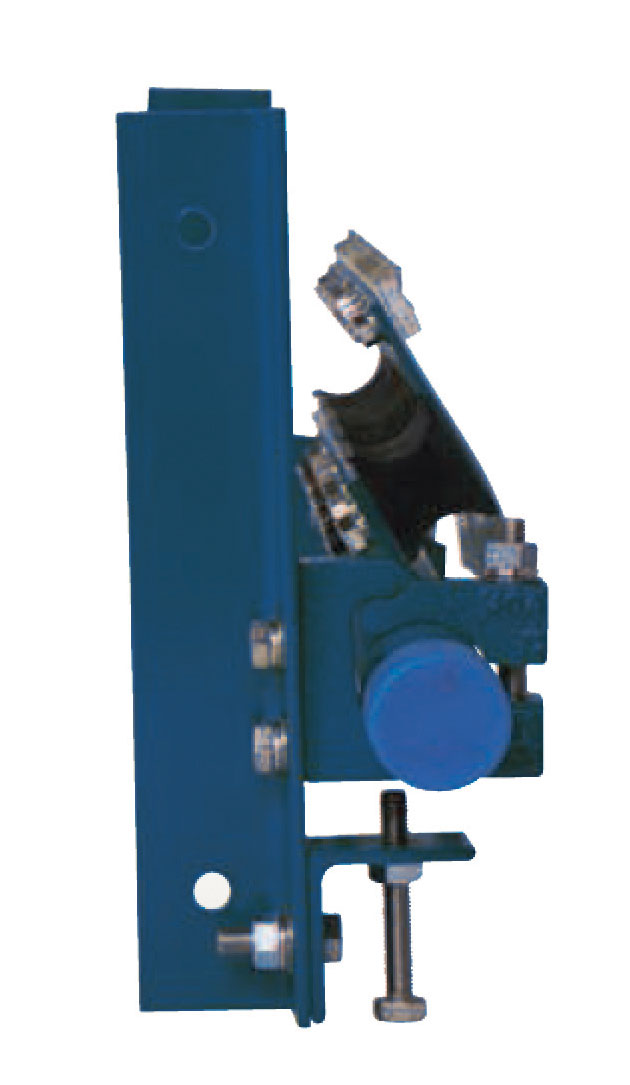

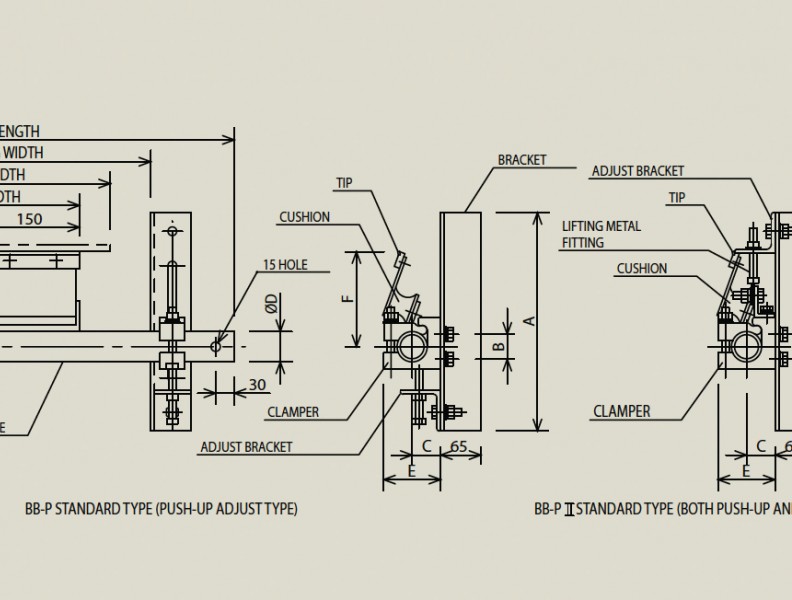

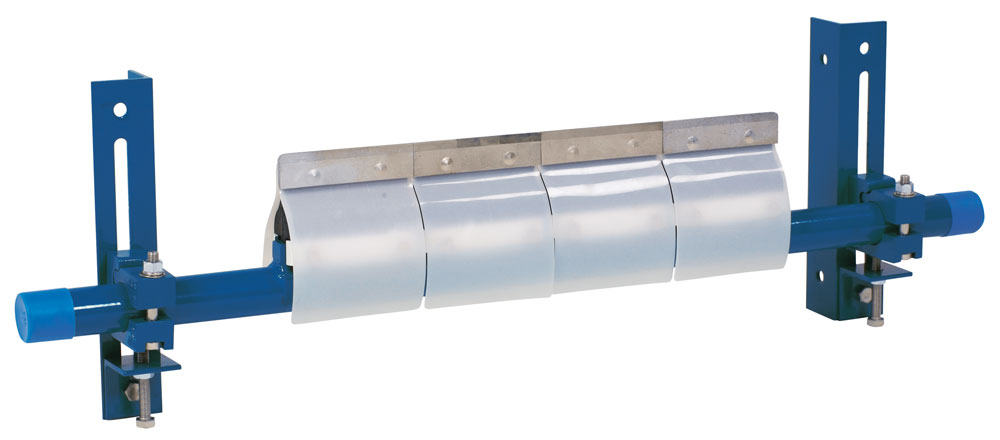

Secondary Cleaner

This is a secondary cleaner with all types of forward rotation conveyors. The cleaner fits just behind the head drum and can be fitted in a small space. It also has the very efficient and high cleaning capacity. The tungsten carbide tips also give it a great durability. This cleaner has by far been our most popular selling type. This is due to the very economical cost.

Features:

- Flexibility, there is no adverse effect on the cleaner if the belt surface is in poor condition.

- No adhesion residue due to the high quality polymer deflectors

- Economical, it has excellent cleaning capabilities, thus saving down time and labour costs

- Low cost cleaner, easy to install within small areas

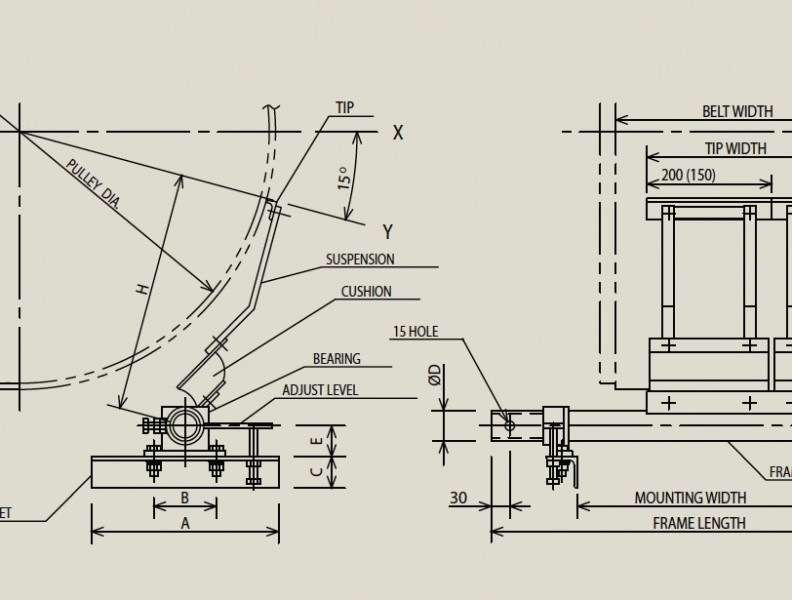

Reversible Cleaner

The R-Type is a secondary belt cleaner designed to run in both directions. It has tungsten carbide blades and rubber cushions, which allow forward and reverse belt direction without damage to the belt. The tip width is 150mm and combined with the rubber cushions provide constant pressure on the belt surface. The cleaner is easily adjusted with a single bolt on each side.

Features:

- Easy to install and only needs a vertical height of 200mm

- Ideal to use on forward or reverse conveyors

- Tungsten carbide blades for long lasting durability

- It can range from 350mm to 2200mm belt widths

U-Type Cleaner

The U-type cleaner is a unique system. The arch shape helps keep consistent pressure on the whole surface of the belt. The arch shape also helps to keep strong pressure on the belt which is good for sticky materials. The U-type is situated on the underside of the belt usually between the head drum and first return roller. It has a single tungsten carbide blade, this is both simple and easy to change.

Features:

- Ultra performance in the conveyance of sticky materials owing to its ability to apply strong pressure

- One complete tungsten carbide blade, for easy maintenance

- Self-torsion tension system. That needs minimal adjusting

- Blade can easily be changed with our one touch cartridge system